While boring a workpiece should be a routine process, many things can go wrong when plunging your machine into a part if you´re not using the right tool for the job.

One of the most common issues is called “walking.” This happens when the drill bit “walks” across the surface of the workpiece, instead of staying in a single spot.

Walking can be caused by several factors, including an uneven surface, incorrect feed rate, or using the wrong type of drill bit.

One way to help prevent walking is by using carbide spot drills. A spot drill is a type of drill bit that is specifically designed to create a small notch or divot on the surface of the workpiece. This divot acts as a “pilot hole” for the larger drill bit, which helps to keep the drill bit in place and prevent it from walking off, giving you increased chances of staying true to your print.

Different tools can perform this job. The most common is using a center drill. A center drill is a two-fluted drill bit that is used to create small holes that allow you to secure your workpiece in a lathe.

The name can confuse those looking to center their jobbers or drills for increased accuracy during boring operations. Also, their price tends to be extremely attractive for those who want to widen profit margins. However, center drills have a few weaknesses that make them a suboptimal tool for operations that require starting multiple holes in your workpieces.

For starters, center drills feature a pilot or cone-shaped point that is considerably thinner than the shaft. Then the “shoulders” are used to create a countersink to make screws lay flush with the workpiece surface. Center drills provide solid starting points for subsequent drilling in many instances.

However, the not-so robust end section tends to break during demanding operations because of its disparity relative to the tool core. This relative weakness creates situations where a workshop spends most of its productive hours on tool change cycles.

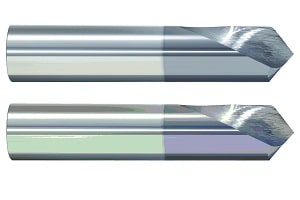

On the other hand, carbide spot drills are specifically designed to provide uniform and accurate performance even during demanding operations on hardened materials.

Spot drills feature a much more robust and thicker cutting section that is designed to withstand the high feed rates and rigors of modern CNC machining.

In terms of overall strength and durability, spot drills are vastly superior to center drills. While center drills may offer a more attractive price point, they simply can’t match the precision or performance of spot drills – making them a poor choice for those looking to produce the highest quality parts possible.

Many factors can affect the quality of your boring operations, and one of the most important is choosing the right type of drill bit. If you’re looking for increased accuracy and precision, then carbide spot drills are a better choice than center drills. Get the best carbide spot drills and tools from reputed manufacturers like Online Carbide. Visit their website and take advantage of their manufacturer direct prices and extensive catalog of high-performance carbide tools.

For more information about Drill Mills For Sale and Best End Mills For Aluminum Please visit: Online Carbide.