We had a recent problem when trying to machine 30:1 holes in 303 stainless steel. The problem was keeping the inch concentricity of the hole at the other end within 0.002 inches, but the tool kept walking off.

Drill wandering is a common occurrence when drilling, but it can be solved with the correct use of a spot drill.

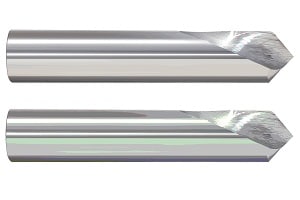

A spot drill is a tool used to create a small divot in the workpiece prior to drilling. This divot serves two primary purposes: first, it provides a starting point for the drill bit so that it minimizes tool wander; and second, it creates a small hole for chip evacuation.

The vast majority of drill bits are not designed to create a starting point on their own. Drills tend to wobble around their axis, and the greater the distance between the point and the spindle, the wider the pendulum effect of your tool when spinning at high speeds. So a spot drill is an essential tool in the machinist’s arsenal.

However, there are other elements that should be considered if you want to achieve maximum straightness:

Consider Your Drill Tip Geometry

When we use, say, 90-degree point angles, hole depth is easy to calculate by dividing the diameter of the pre-spotted hole. However, sometimes we notice that the resulting chamfer is a bit larger. This happens because sometimes the true point of your spot drill has been ground off during the sharpening process. So your tool will preserve its 90° angle, but the touchpoint will be slightly off, making it imperative to consider purchasing carbide spot drills from reputed manufacturers like Online Carbide. They make tools that are precisely centered relative to their shanks, allowing for more accurate measurements.

Get Precision Tool Holders

You can greatly reduce tooltip runout by using precision collet holders that offer reduced tool runout. Traditional collets do not tend to be as accurate, making it almost impossible to reduce wandering at the operative RPM. We recommend on-size precision collet holders that can guarantee dynamic tool runout below the 2 microns mark.

Reduce The Retract Amount Of Peck Cycles

Drill pecking is the process of breaking up a large hole into smaller increments. This is done by drilling a series of small holes, each slightly larger than the last until the final hole size is achieved.

The main advantage of drill pecking is that it minimizes tool chatter and walk-off. It also allows for better chip evacuation, which reduces heat build-up and tool wear.

However, if the retract amount makes the tooltip exit the top of the hole, you might experience a lot of “rubbing” each time the drill engages and disengages the material. This, of course, will affect tool sharpness and contribute to lead-off, making it extremely difficult to stay true to print. So, consider reducing the retract amount to decrease rubbing, increase tool life, and reduce wandering.

Use A Stiffer Drill Body

One other reason why a drill will walk is that it’s not rigid enough. If your drill is deflecting, it will most likely wander off course. That’s why we recommend using a stiffer drill body whenever possible. The added rigidity will help keep the tool on track, thus reducing tool deflection.

Carbide tools are typically much stiffer than their HSS counterparts and will offer better results in this regard. We highly recommend tools made in the US as they offer higher quality control standards. Visit Online Carbide and find out more about their highly precise spot drills and carbide tools.

For more information about End Mills For Sale and Drill Mills For Sale Please visit: Online Carbide.